Corrosion. It is the cancer of infrastructure worldwide.

It is a 6 Trillion dollar problem globally, per year. In Australia, the cost of addressing corrosion-related issues is 4-5% of GDP!

Giles Harrison, TECHT’s Principal Corrosion Engineer has been working for over two (2) decades throughout several industries to assist asset owners in reducing this cost, improving safety and environmental outcomes, and avoiding reputational damage due to corrosion-related failures.

Asset integrity is a fundamental requirement of operational reliability across all industries. The equipment can’t work if there is nothing to support it.

In today’s work environment, where asset downtime can result in significant financial losses and safety risks, effective corrosion management is paramount. In this post, we touch on the importance of emerging technologies in shaping the future of corrosion management and their implications for industries reliant on infrastructure and equipment durability.

Specifically, how predictive analytics, advanced sensors, robotics, nanotechnology, and other innovative solutions are revolutionising asset protection and maintenance practices.

TECHT is working to provide the industry with innovative corrosion and integrity management services for a sustainable future. This discussion acts as a conversation starter and provides some insights into the transformative power of technology in safeguarding critical assets and ensuring operational resilience.

As industries continue to push the boundaries of innovation, the field of corrosion management is also undergoing a transformation, driven by emerging technologies that promise to revolutionise how we approach asset protection and longevity.

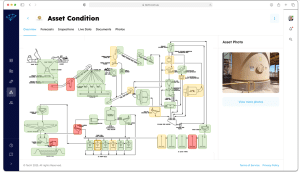

One promising advancement lies in the realm of predictive analytics and artificial intelligence (AI). Leveraging the power of data analytics and machine learning algorithms, predictive maintenance models can now forecast corrosion events with unprecedented accuracy. By analysing historical data, monitoring real-time conditions, and detecting subtle patterns, AI-driven systems can predict potential corrosion risks before they escalate, enabling proactive interventions and substantial cost savings.

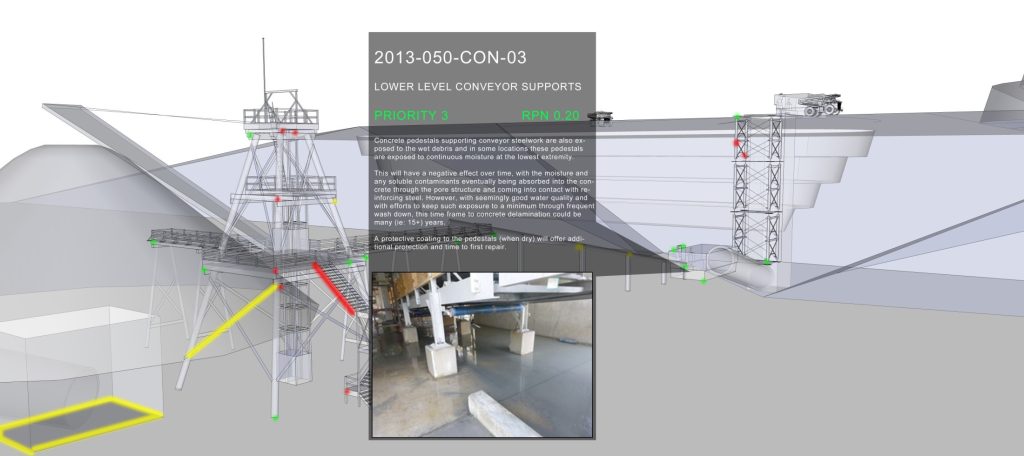

Another technology poised to reshape corrosion management is the advent of advanced sensors and monitoring devices. From wireless corrosion sensors to remote monitoring platforms, these cutting-edge technologies provide real-time insights into asset health and performance. By continuously monitoring environmental conditions, material degradation, and corrosion rates, these sensors empower asset managers with actionable data, facilitating timely maintenance and mitigating corrosion-related risks.

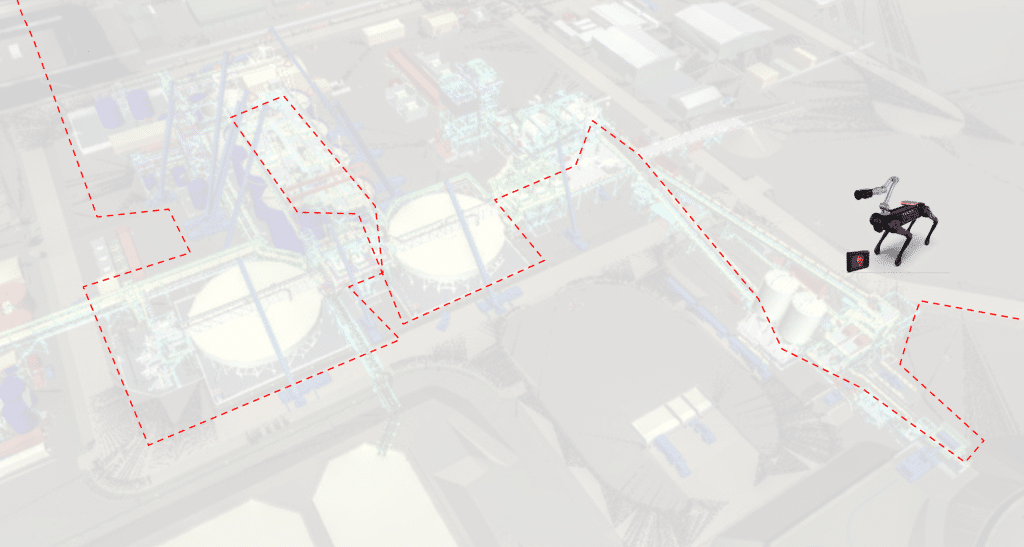

We are already seeing the integration of robotics and automation processes holding immense potential in streamlining inspection and maintenance processes. Autonomous drones equipped with high-resolution cameras and sensors can navigate complex industrial environments, conducting thorough inspections and identifying corrosion hotspots with unparalleled efficiency. Additionally, robotic systems capable of performing in-situ repairs and protective coatings application minimise human intervention in hazardous environments, ensuring worker safety while optimising asset uptime.

The emergence of nanotechnology presents yet another frontier in corrosion management, offering novel solutions for surface protection and material enhancement. Nanocoatings, engineered at the molecular level, exhibit exceptional corrosion resistance and durability, providing superior protection against environmental degradation and chemical exposure.

Additionally, nanomaterials infused with self-healing properties can autonomously repair micro-damage, extending the lifespan of critical assets and reducing maintenance costs over time.

As we embark on this journey toward the future of corrosion management, TECHT remains at the forefront of innovation, embracing these emerging technologies to deliver unparalleled solutions to our clients.

With our unwavering commitment to excellence and cutting-edge expertise, we are poised to shape a future where asset integrity is not just maintained, but optimised for sustained performance and longevity.

Join us in harnessing the power of innovation as we pave the way for a brighter, corrosion-free tomorrow.