Empowering Industry Through Excellence in Corrosion and Microbiological Testing

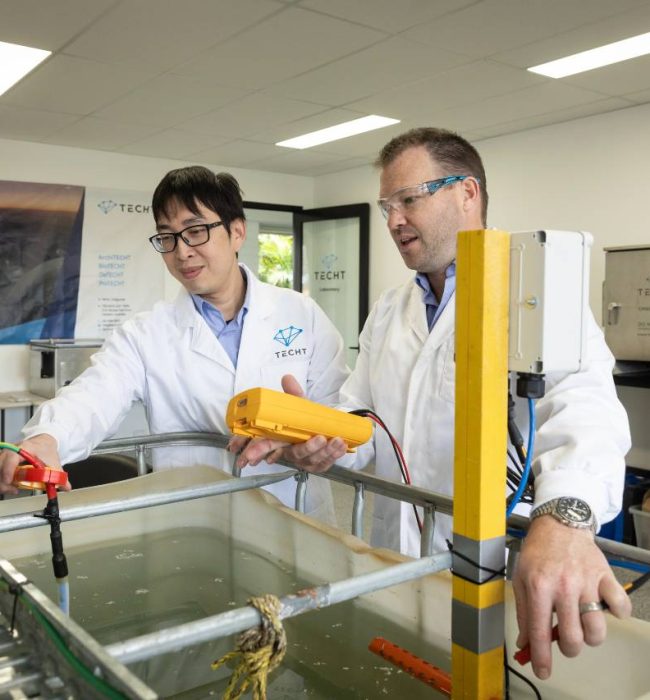

TECHT proudly operates a state-of-the-art Corrosion Testing Laboratory in Technology Park, Bentley (Perth, Western Australia), delivering high-quality, locally accessible services to industries and government agencies across Australia.

Supported by The Department of Energy and Economic Diversification (DEED) and trusted by major industries nationwide, our facility is built to Physical Containment Level 2 (PC2) standards and complies with Australian regulations.

Our laboratory is purpose-built for corrosion testing and analysis, with a strong focus on infrastructure and asset-intensive industries.

TECHT’s laboratory operates in line with the highest standards of safety, performance, and accuracy, including:

Our advanced methodologies and sampling capabilities ensure accurate detection, monitoring, and mitigation of microbial corrosion risks.

Our Sampling Kits enable testing of:

View our full DNA Sampling Kit Capabilities.

Review our Biocide Effective Testing capabilities.

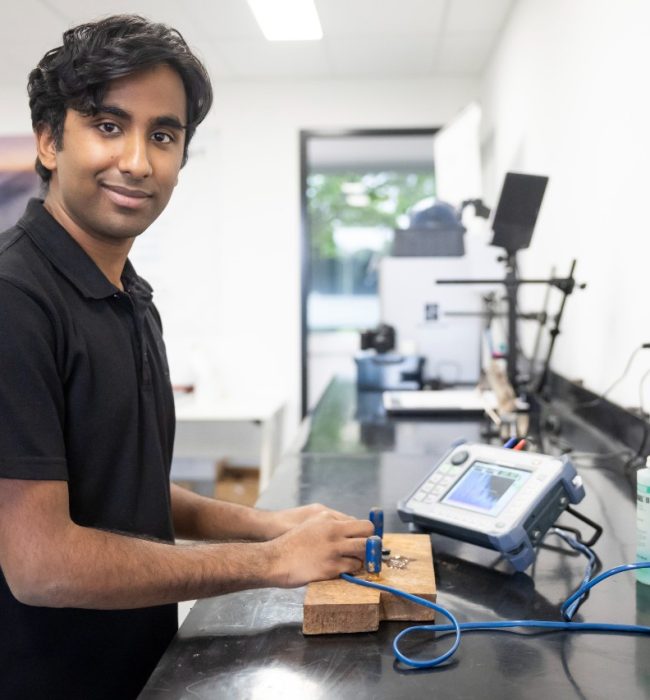

Fit-for-purpose testing for Microbiologically Influenced Corrosion (MIC) involves using a range of analytical methods to assess material degradation in specific operational environments.

Corrosion coupon analysis is a proven and cost-effective method for assessing corrosion rates and environmental aggressiveness over time.

At TECHT, our laboratory provides corrosion coupon testing in alignment with industry standards including AMPP SP0775-2013 and AMPP TM0212-2018. This service allows asset owners and engineers to:

Corrosion by Weight Loss Analysis can be conducted on a wide range of materials following National and International Standards at the TECHT Laboratory:

Our corrosion consultants work closely with clients to interpret coupon data and integrate findings into broader asset integrity and corrosion management solutions.

Assessing adhesion strength, coating integrity, cathodic disbondment, and chemical resistance using Australian Standard-compliant corrosion testing methods.

TECHT’s in-house facility conducts certified protective coating testing to ensure coating systems perform as expected under harsh environmental conditions.

Our corrosion engineering services in Perth support manufacturers, contractors, and asset owners with reliable evaluations to prevent premature coating failures and support QA/QC across asset lifecycles.

TECHT has established a Corrosion Testing Laboratory in Technology Park (Bentley, WA), offering localised, high-quality services for industries and government agencies across Australia.

Whether you’re an Australian-based mining operator or an engineering consultant, our corrosion consulting services provide the data you need to make informed decisions and implement resilient corrosion management programs.

Our laboratory evaluates factors such as chloride ingress, carbonation depth, compressive strength, and alkali-silica reaction susceptibility.

We deliver specialised concrete testing services tailored to harsh environments and corrosive exposures common in industrial, marine, and mining applications.

These insights are critical for engineers and asset managers seeking durable design engineering and corrosion mitigation strategies for concrete structures in Western Australia and beyond.

Supporting both public and private sector innovation with access to highly specialised corrosion engineering knowledge and real-world testing environments. research, development, and innovation on your behalf.

TECHT is committed to pushing the boundaries of corrosion science. Our laboratory team collaborates with clients, universities, and research bodies to deliver custom R&D programs focused on corrosion mechanisms, new material performance, and novel mitigation techniques.

Laboratory testing work has assisted us by simulating process conditions to allow data driven decisions on material selection. Really enjoyed working with the BioTECHT team.

“TECHT was able to assist site personnel to ensure the job got done when undertaking planned maintenance inspections. Service that is over and above.”

“Structural integrity items encompass structural steel and concrete structures that are designed to last for the life of the operation. When the life of mine is extended, action needs to be taken. TECHT engineers assisted in setting up the Structural Integrity Reliability Program at our plant to ensure our structures are fit for purpose for the extended life.”

“TECHT engineers undertook a range of inspections that satisfy our statutory internal and external asset inspection requirements, to a high standard.”

“TECHT undertook a corrosivity assessment of our site and developed a corrosion mitigation plan strategy based on the findings. The report allowed us to downgrade material specifications with confidence, saving the project hundreds of thousands.”

Sustainability Achieved through Durable Design Engineering

Microbiologically Influenced Corrosion (MIC), Biofouling, Biodegradation and Biodeterioration

Complete Corrosion Engineering Services

Condition Monitoring & Automation